Title: Stepper Motor Speed Control

In the realm of industrial automation and precision control systems, the significance of stepper motors cannot be overstated. These motors, characterized by their ability to move in precise increments, find extensive use in a wide array of applications, ranging from 3D printing and CNC machines to robotics and automated manufacturing processes. As the demand for precise motion control continues to grow, so does the need for advanced research and development in the domain of stepper motor control.

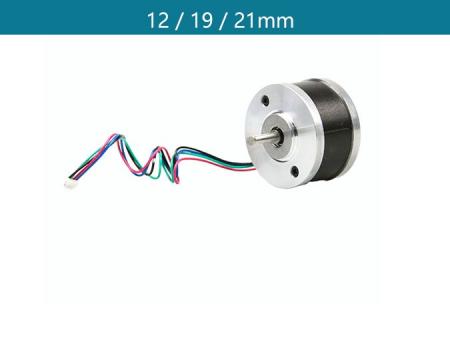

One prominent player in this arena is the brand "Jkongmotor," which has been at the forefront of developing innovative solutions for stepper motor control. The focus of this discourse is to delve into the intricacies of stepper motor speed control, shedding light on the challenges and strategies associated with managing acceleration, deceleration, and overall speed regulation in these critical components.

The fundamental principle governing the speed of a stepper motor lies in its pulse frequency, rotor teeth count, and steps per revolution. The angular velocity of the motor is directly proportional to the pulse frequency, synchronizing with the pulse in time. Thus, given a fixed rotor teeth count and step configuration, the desired speed can be achieved by controlling the pulse frequency. However, it's crucial to note that due to the motor's reliance on its synchronous torque for initiation, high starting frequencies must be avoided to prevent step loss. This becomes particularly pronounced with increasing power, as larger rotor diameters and inertias necessitate significantly disparate starting and maximum operating frequencies.

The characteristic startup frequency of stepper motors necessitates a gradual acceleration process, wherein the motor transitions from a low speed to its operational speed. Similarly, during shutdown, the operational frequency cannot instantaneously drop to zero, requiring a high-speed deceleration process to come to a halt. This inherent nature of stepper motors demands a nuanced approach to speed control, emphasizing the need for carefully orchestrated acceleration, uniform speed, and deceleration phases.

Moreover, the output torque of a stepper motor diminishes as the pulse frequency increases. Higher startup frequencies result in reduced starting torque, thereby compromising the motor's ability to drive loads and potentially leading to step loss during the initiation phase. Conversely, during shutdown, overshooting becomes a concern. To ensure that the stepper motor rapidly attains the required speed without experiencing step loss or overshooting, it is imperative to strike a delicate balance during the acceleration process. This involves leveraging the torque provided by the motor at various operating frequencies without exceeding its limits. Consequently, the operation of a stepper motor typically involves three distinct stages: acceleration, constant speed, and deceleration, with an emphasis on minimizing the duration of the acceleration and deceleration phases while maximizing the time spent at a constant speed.

In applications where rapid responsiveness is paramount, the time taken to traverse from the starting point to the endpoint must be minimized, necessitating swift acceleration and deceleration processes, coupled with sustained high-speed operation during the constant speed phase.

In conclusion, the control of stepper motor speed, particularly in the context of acceleration and deceleration, presents a multifaceted challenge that demands a meticulous understanding of the motor's operational characteristics and a nuanced approach to pulse frequency modulation. As the demand for precision motion control continues to surge across diverse industrial domains, the quest for efficient and effective stepper motor speed control mechanisms remains a critical frontier in the realm of automation and control systems.

Through sustained research, innovation, and collaboration, industry leaders like Jkongmotor are poised to drive the evolution of stepper motor control, ushering in an era of heightened precision, reliability, and efficiency in motion control systems.

View More(Total0)Comment Lists