Brushless motors have become a cornerstone in various industries due to their high efficiency, durability, and precise control. Among the different types of brushless motors, sensored and sensorless variants are the most commonly used, each offering distinct advantages depending on the application. Understanding the difference between these two motor types is crucial for selecting the right motor for a specific purpose. In this article, we will explore the key differences between sensored and sensorless brushless motors, their advantages, and the ideal use cases for each.

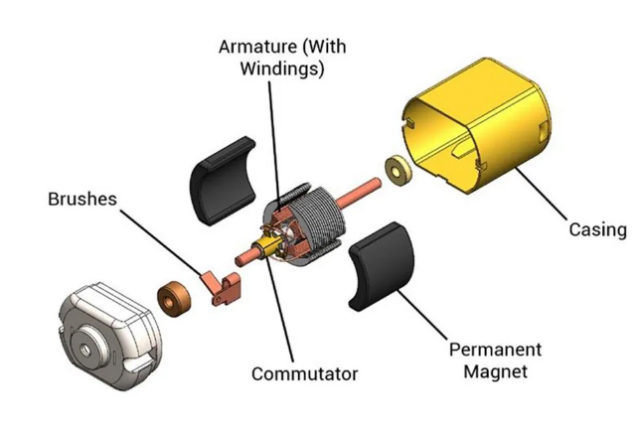

Before delving into the specifics of sensored and sensorless Brushless motors, it's important to understand what a brushless motor is. A brushless motor (BLDC) is a type of electric motor that uses permanent magnets on the rotor and electromagnets on the stator. Unlike traditional brushed motors, which rely on brushes to switch the current direction, brushless motors use an electronic controller to drive the current, which results in higher efficiency, less wear and tear, and a longer operational lifespan.

Brushless motors come in two primary types: sensored and sensorless, both of which differ in the way they detect rotor position and deliver power.

A sensored Brushless motor uses position sensors (typically Hall sensors) to continuously monitor the rotor's position and provide feedback to the electronic controller. These sensors send real-time data to the controller, allowing it to adjust the timing of the current applied to the motor coils for smooth operation. This feedback mechanism ensures the motor’s rotor is accurately aligned with the stator, enabling precise control of speed and torque.

The use of position sensors allows for precise control over the rotor's location, ensuring smooth starts and operation even at low speeds.

Sensored motors excel in applications that require low-speed operation with consistent torque and minimal vibration.

Because the motor has position feedback, the controller can apply the right amount of torque when the motor starts, providing higher starting torque compared to sensorless designs.

In systems that demand precise torque control, sensored motors can optimize energy usage and ensure better overall performance.

A sensorless Brushless motors, on the other hand, does not rely on position sensors. Instead, it uses the back electromotive force (back EMF) generated by the motor during operation to detect rotor position. The controller detects the back EMF from the stationary motor and uses this information to determine when to switch the current to the appropriate coils. This allows the motor to operate without the need for external sensors.

Sensorless motors do not use any sensors to track rotor position, which reduces their complexity and cost.

With fewer components, sensorless motors are typically more robust and less prone to failure, making them ideal for applications that demand reliability.

While sensorless Brushless motors may struggle at low speeds, they can achieve excellent efficiency and performance at higher speeds due to their simpler design.

The lack of sensors makes sensorless motors more cost-effective compared to sensored motors, which can be important in large-scale applications or where budget constraints are a factor.

Sensored Motors: Use position sensors (Hall sensors) to constantly monitor and adjust the rotor's position, ensuring smooth operation.

Sensorless Motors: Rely on back EMF to estimate rotor position, and therefore don’t provide constant feedback like sensored motors.

Sensored Motors: Have higher starting torque and can provide a smooth start even at very low speeds.

Sensorless Motors: May have lower starting torque and can struggle to start smoothly at low speeds without additional circuitry.

Sensored Motors: More complex due to the inclusion of sensors, which increases their cost and makes them slightly more difficult to maintain.

Sensorless Motors: Simpler, with fewer components (no sensors), which leads to lower manufacturing costs and easier maintenance.

Sensored Motors: Offer precise speed and torque control, especially at low speeds, making them ideal for applications requiring accuracy and stability.

Sensorless Motors: Typically more efficient at higher speeds, but their performance can degrade at lower speeds due to the lack of real-time position feedback.

Sensored Motors: The additional components (such as sensors) can increase the risk of failure, particularly in environments with high vibration or moisture.

Sensorless Motors: Are more durable and reliable in harsh environments due to their simpler design, as there are fewer parts that can wear out or break down.

Sensored Motors: Best suited for applications requiring precise control at low speeds, such as robotics, CNC machines, or electric vehicles.

Sensorless Motors: Ideal for applications where high-speed performance is crucial, such as power tools, drones, or automotive systems.

They are two types of Brushless motors. The sensorless brushless motor senses the state and position of the rotor through the Hall element in the motor, and the sensorless countless motors use the ESC back EMF signal to determine the rotor position commutation. The sensorless brushless motor can know the position of the rotor in a static state, and the sensorless brushless motor can only be judged when it rotates, so the sensorless brushless motor will shake when it just starts, and it is difficult to control at low speed. The sensored brushless motor uses Hall element induction, which is not easy to be disturbed and the judgment is more accurate.

Advantages: The linearity of the sensored Brushless motor is better, the speed stability is strong, and the response is high.

Disadvantages: high cost, and not waterproof. Due to the limitation of the Hall sensor, it is easy to interfere, so the driver receives the wrong information and causes the failure. Therefore, the length of the line from the driver to the motor is generally limited to within 5 meters.

Advantages: Sensorless Brushless motors cost less. Wire length is not limited by the influence of the Hall sensor.

Disadvantages: Linear is not as good as sensored brushless motors. In addition, because the driver does not have accurate feedback on the speed, the error will be more than ±20 rpm. It is easy to shake or fail to start with load and full load.

Ideal for applications requiring slow, steady movement with consistent torque.

Provides better torque at startup, which is useful in load-heavy systems.

Perfect for applications that need jerk-free motion and precise control, like in medical equipment or robotic arms.

Without the need for sensors, these motors tend to be cheaper and easier to produce.

With fewer components, sensorless Brushless motors are easier to maintain and more reliable over time.

Ideal for high-speed applications like drones or remote-controlled cars, where the motor operates at a constant, high RPM.

The decision between sensored and sensorless Brushless motors largely depends on the specific requirements of your application. If your system needs precise control at low speeds and high starting torque, a sensored motor is likely the better choice. These motors excel in environments where accuracy and reliability are paramount, such as in robotics or medical devices.

On the other hand, if your system operates at high speeds or in environments where cost and durability are more important, a sensorless motor may be the ideal choice. These motors are more efficient at higher speeds and offer the benefit of reduced complexity, making them a preferred option in automotive applications, power tools, or drones.

Both sensored and sensorless Brushless motors offer distinct advantages and have their place in a wide range of applications. Sensored motors provide precise control, higher starting torque, and smooth low-speed performance, making them ideal for systems requiring high accuracy and stability. Sensorless motors, on the other hand, are simpler, more cost-effective, and perform efficiently at high speeds, making them suitable for applications where robustness and efficiency are prioritized over low-speed precision.

View More(Total0)Comment Lists