A Brushless DC (BLDC) motor is an electric motor that operates using direct current (DC) but does not require mechanical brushes for commutation. Instead, it uses electronic commutation to control the current flow in the motor windings, making it more efficient, durable, and reliable than conventional brushed motors.

A BLDC motor consists of two main components:

Stator: The stationary part that contains copper windings. When these windings are energized in sequence, they create a rotating magnetic field.

Rotor: The rotating part that contains permanent magnets. The interaction between the stator’s magnetic field and the rotor’s magnets generates torque, causing the rotor to turn.

BLDC motors operate based on the principle of electromagnetic induction. The stator windings are energized in a specific sequence, creating a rotating magnetic field. This field interacts with the rotor’s magnets, causing the rotor to follow the rotating field and produce continuous motion.

The switching of current in the windings is managed by an Electronic Speed Controller (ESC). Hall sensors or position encoders provide real-time rotor position feedback to the controller, which ensures that the correct windings are energized at the right time, allowing smooth and efficient rotation.

These motors use Hall sensors to detect the rotor's position and adjust the commutation accordingly.

Sensorless motors rely on back EMF (Electromotive Force) generated by the rotor’s motion to determine its position, eliminating the need for Hall sensors.

Back Electromotive Force (Back EMF) is the voltage generated by the rotor’s motion through the stator’s magnetic field in a Brushless DC (BLDC) motor. This voltage opposes the applied voltage and is directly proportional to the motor’s speed. Understanding how to calculate back EMF is essential for designing motor controllers and optimizing motor performance.

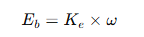

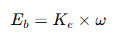

The back EMF of a BLDC motor can be calculated using the following formula:

Where:

Eb = Back EMF (Volts)

Ke = Back EMF constant (Volts per radian per second or Volts per RPM)

ω = Angular velocity of the rotor (Radians per second or RPM)

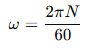

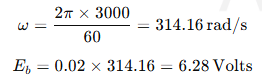

If the motor speed is given in Revolutions Per Minute (RPM), it must be converted to Radians Per Second (rad/s) using the formula:

Where:

N = Rotor speed in RPM

2π = Conversion factor to radians

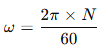

If the motor speed is given in RPM, convert it to radians per second:

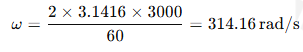

For example, if the motor is running at 3000 RPM:

The back EMF constant is often provided in motor datasheets. It can be specified as:

Volts per RPM

Volts per radian per second

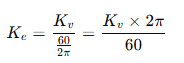

If the value is given in Volts per RPM, it needs to be converted to Volts per radian per second:

Where:

Kv is the motor’s speed constant (RPM per Volt)

Using the formula:

Substitute the values to find the back EMF.

Consider a BLDC motor with:

Speed N=3000 RPMN

Back EMF constant Ke=0.02 Volts per rad/s

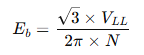

If the motor’s back EMF is given as a line-to-line value, the formula becomes:

Where:

VLL = Line-to-line back EMF voltage

N = Rotor speed in RPM

Accurate back EMF calculation helps design motor controllers that can effectively regulate motor speed and torque.

Since back EMF increases with speed, knowing the maximum generated voltage helps protect the system from overvoltage conditions.

Calculating back EMF allows fine-tuning of motor parameters to achieve maximum efficiency under different load conditions.

Higher Efficiency: Less energy is lost due to friction and heat.

Longer Lifespan: No brushes mean less wear and tear.

Precise Control: Suitable for applications requiring speed and torque control.

Lower Maintenance: No need for periodic brush replacement.

BLDC motors are widely used in various industries due to their efficiency and reliability. Common applications include:

Electric Vehicles (EVs) and Hybrid Cars

Drones and Robotics

Home Appliances (Fans, Washing Machines, Air Conditioners)

Industrial Automation and CNC Machines

HVAC Systems

The BLDC motor has revolutionized the electric motor industry by offering higher efficiency, longer lifespan, and greater control over speed and torque. Its applications span from everyday household appliances to complex industrial systems, making it a preferred choice in modern technology.

Calculating the back EMF of a BLDC motor is essential for efficient motor control and protection. By using the appropriate formula and converting units correctly, accurate back EMF values can be obtained, ensuring optimal performance and longevity of the motor.

View More(Total0)Comment Lists