Linear actuators, integral components of modern automation and control systems, are devices that convert rotational motion into linear motion. These technological marvels facilitate a myriad of applications across various sectors, ranging from manufacturing to healthcare, aerospace to home automation. This essay delves into the multifaceted roles linear actuators play in contemporary society, examining their mechanisms, types, and diverse applications, while also considering their impact on efficiency and innovation.

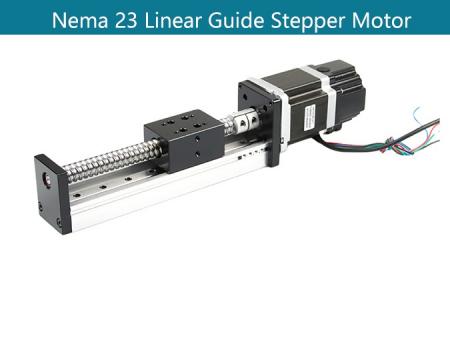

At its core, a linear actuator is a device that provides straight-line motion, a function that is crucial in applications requiring precision and controlled movement. Linear motion can be generated through various means, including electric motors, pneumatic systems, and hydraulic systems. Electric linear actuators are particularly popular due to their ease of control, energy efficiency, and the ability to integrate seamlessly with computer systems.

The main types of linear actuators include electric actuators, hydraulic actuators, pneumatic actuators, and mechanical actuators. Electric actuators utilize an electric motor, often coupled with a screw drive or a belt drive, to translate rotational motion into linear motion. Hydraulic actuators, on the other hand, use pressurized fluid to create motion, offering high power and efficiency for heavy-load applications. Pneumatic actuators operate on compressed air, providing rapid movement for applications where speed is essential, while mechanical actuators rely on physical components such as levers and gears to effect movement.

One of the most significant applications of linear actuators lies in the manufacturing sector, where they are employed to enhance productivity and precision. In automated assembly lines, linear actuators can control the positioning of tools and assembly parts with remarkable accuracy. They facilitate processes such as robotic arms performing tasks ranging from welding to packaging, significantly decreasing cycle times and minimizing human error.

In material handling, linear actuators automate conveyor systems and robotic pick-and-place operations, enabling seamless movement of goods throughout facilities. Such applications not only improve efficiency but also enhance worker safety by reducing manual handling tasks.

The healthcare industry also benefits immensely from the application of linear actuators. They are crucial in medical devices and equipment, such as hospital beds, surgical tables, and patient lifts. Electric linear actuators allow for the easy adjustment of bed heights and positions, catering to patient comfort and facilitating medical procedures. Furthermore, in rehabilitation technologies, linear actuators power assistive devices that help patients regain mobility and independence.

Linear actuators are also integrated into diagnostic equipment, such as MRI machines and X-ray devices, where precise positioning is paramount. The high reliability and accuracy of linear actuators serve to improve the safety and efficacy of medical procedures.

In the aerospace sector, linear actuators are indispensable in the operation of various systems within aircraft and spacecraft. Their applications include controlling flaps and slats on wings, actuating landing gear, and adjusting cockpit controls. Given the stringent safety and performance standards in this field, the reliability of linear actuators is crucial.

Similarly, in the defense industry, they are employed in weapon systems, robotic vehicles, and surveillance equipment, ensuring precise control under demanding conditions. The ability of these actuators to function effectively across a range of temperatures and environments enhances their operational reliability in critical applications.

The rise of smart home technologies has further expanded the application of linear actuators into residential settings. Home automation systems utilize linear actuators to control window blinds, awnings, and garage doors, providing convenience and energy efficiency. For instance, automated curtain systems can adjust according to the time of day, optimizing natural light use and enhancing energy efficiency in homes.

Moreover, linear actuators are increasingly being integrated into furniture designs, allowing for adjustable desks and beds that enhance ergonomics and comfort. The integration of these actuators with smart technology enables users to customize their environments, improve productivity, and enhance overall quality of life.

In agriculture, linear actuators play a pivotal role in the automation of various farming processes. They are used in planting, irrigation, and harvesting equipment, providing precise control over machinery movements. For instance, linear actuators can adjust the height of planting equipment, ensuring optimal seed placement. Additionally, they facilitate the automation of irrigation systems, enabling farmers to optimize water usage and enhance crop yields through precise control of water flow.

The application of linear actuators contributes significantly to innovation and efficiency across sectors. By automating tasks and providing precise control, they allow for enhanced productivity and reduced operational costs. The integration of linear actuators into advanced control systems facilitates real-time monitoring and automation, driving forward the development of Industry 4.0 paradigms.

Moreover, the adaptability of linear actuators to various environments ensures their relevance in future applications, including robotics, transportation, and energy systems. As technology continues to evolve, the potential for innovative uses of linear actuators appears boundless.

In conclusion, linear actuators serve as crucial components in a myriad of applications across diverse industries. Their ability to convert rotational motion into linear motion facilitates automation, efficiency, and precision, significantly contributing to advancements in manufacturing, healthcare, aerospace, home automation, and agriculture. As technology progresses, the role of linear actuators is likely to expand even further, underpinning innovations that enhance human capabilities and improve productivity. The ongoing advancements in actuator technology will undoubtedly continue to shape the landscape of automation and control systems, making linear actuators a cornerstone of modern engineering solutions.

View More(Total0)Comment Lists