Genaral Characteristic:

| Frame number(mm) | Working voltage(VAC) | Rated speed(rpm) | Maximum speed(rpm) | Rated power(kW) | Rated torque(Nm) |

| 40~180 | 220/380 | 1000~3000 | - | 0.05~7.5 | 0.16~48 |

| Insulation class | Installation mode | Pole pairs | Temperature | Humidity | Safety class |

| B/F | Flange | 4 | -20~40℃ | Less than 90% (No condensation) | IP65 |

180ST AC Servo Motor Feature:

Type: 180ST-M17215 / 180ST-M19015 / 180ST-M21520 / 180ST-M27010 / 180ST-M27015 / 180ST-M35010 / 180ST-M35015 / 180ST-M48015 AC servo motor

Rated Power: 2.7KW / 2.9KW / 3KW / 3.7KW / 4.3KW / 4.5KW / 5.5KW / 7.5KW

Rated voltage: 220V / 380V

Rated speed : 1000RPM / 1500RPM / 2000RPM

Rated torque: 17.2N.m / 19N.m / 21.5N.m / 27N.m / 35N.m / 48N.m

Encoder Line Number: 2500PPR

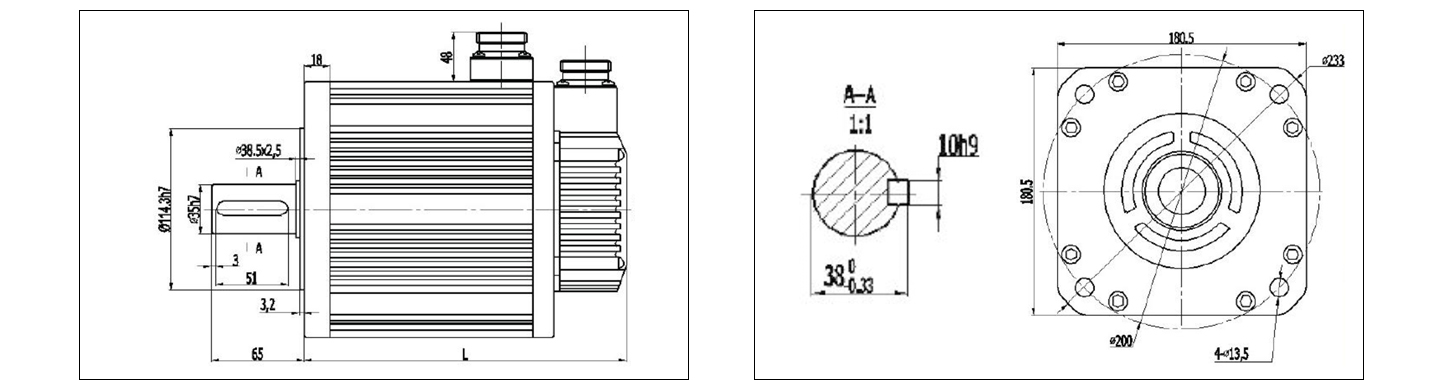

Installation dimensions:

| Motor type | 180ST- M17215 | 180ST- M19015 | 180ST- M21520 | 180ST-M27010 180ST-M27015 | 180ST-M35010 180ST-M35015 | 180ST– M48015 | |||||||

| L(mm)(Without brake) | 226 | 232 | 243 | 262 | 292 | 346 | |||||||

| L(mm)(With permanent magnet brake) | 308 | 314 | 325 | 344 | 382 | 436 | |||||||

| L(mm) With electromagnetic break | 298 | 304 | 315 | 334 | 364 | 418 |

180mm AC Servo Motor Parameters:

| Motor type | 180ST- M17215 | 180ST- M19015 | 180ST- M21520 | 180ST- M27010 | 180ST- M27015 | 180ST- M35010 | 180ST– M35015 | 180ST– M48015 | ||||||||

| Rated power(KW) | 2.7 | 3.0 | 4.5 | 2.9 | 4.3 | 3.7 | 5.5 | 7.5 | ||||||||

| Rated voltage(V) | 220 | 380 | 220 | 380 | 220 | 380 | 220 | 380 | 220 | 380 | 220 | 380 | 220 | 380 | 220 | 380 |

| Rated current(A) | 10.5 | 6.5 | 12 | 7.5 | 16 | 9.5 | 12 | 7.5 | 16 | 10 | 16 | 10 | 24 | 12 | 32 | 20 |

| Rated speed(rpm) | 1500 | 1500 | 2000 | 1000 | 1500 | 1000 | 1500 | 1500 | ||||||||

| Rated torque(N.m) | 17.2 | 19 | 21.5 | 27 | 27 | 35 | 35 | 48 | ||||||||

| Peak torque(N.m) | 43 | 47 | 53 | 67 | 67 | 70 | 70 | 96 | ||||||||

| Voltage constant(V/Krpm) | 112 | 167 | 97 | 170 | 84 | 140 | 138 | 224 | 103 | 172 | 134 | 223 | 90 | 181 | 94 | 156 |

| Torque coefficient(N.m/A) | 1.64 | 2.65 | 1.58 | 2.5 | 1.34 | 2.26 | 2.25 | 3.6 | 1.69 | 2.7 | 2.2 | 3.5 | 1.5 | 2.9 | 1.5 | 2.4 |

| Rotor inertia(Kg.m²) | 3.4×10-3 | 3.8×10-3 | 4.7×10-3 | 6.1×10-3 | 6.1×10-3 | 8.6×10-3 | 8.6×10-3 | 9.5×10-3 | ||||||||

| Line-Line resistace (Ω) | 0.7 | 1.47 | 0.4 | 1.23 | 0.24 | 0.71 | 0.48 | 1.37 | 0.28 | 0.80 | 0.31 | 0.93 | 0.14 | 0.62 | 0.10 | 0.27 |

| Line-Line inductance(mH) | 3.5 | 7.8 | 2.42 | 7.3 | 1.45 | 4 | 3.26 | 8.6 | 1.74 | 4.83 | 3.28 | 9.1 | 1.00 | 4.00 | 0.77 | 2.14 |

| Electrical time constant(ms) | 5 | 5.3 | 6 | 5.93 | 6 | 5.60 | 6.79 | 6.27 | 6.2 | 6.0 | 10.6 | 9.8 | 7.14 | 6.45 | 7.40 | 7.80 |

| Weight(Kg) | 19.5 | 20.5 | 22.2 | 25.5 | 25.5 | 30.4 | 30.5 | 40.0 | ||||||||

| Insulation class | Class F | |||||||||||||||

180ST AC Servo Motor Dimensions:

AC Servo Motor Features:

1、Design scheme: adopt a new electromagnetic design scheme, lower temperature rise, small motor inertia

2、Application areas: robotics, 3C and other consumer electronics industries

Related Servo Motor Drivers Parameters:

1、Input voltage: Single-phase or three-phase 220~ 380VAC ( -15~+10%), 50~60HZ

2、Control mode: Position control, speed control, torque control

3、Type of encoder: 2500-line incremental type photoelectric encoder ,23-bit absolute value encoder

4、Communication method: RS485, RS232, CANopen, standard MODBUS communication

3、Input and output points: IO programmable supports positive and negative logic settings and function of relocation, 4-channel input supports 16 functions configuration, 3-channel output supports 12 functions configuration

4、Monitoring capabilities: Provide 16 states monitor like location, speed, current, voltage, input and output

Rated 220V output power reference table:

| Code | 04 | 08 | 15 | 22 | 30 | 50 |

| Output power | 0.4kW | 0.75kW | 1.5kW | 2.2kW | 3kW | 5kW |

Rated 380V output power reference table:

| Code | 15 | 25 | 35 | 55 | 75 |

| Output power | 1.5kW | 2.5kW | 3.5kW | 5.5kW | 7.5kW |

Servo Motor Driver Dimensions:

Servo Driver Features:

1、Small in volume and compact in size, which greatly saves the installation space

2、Strong internal position model can plan multi-path in continuous operation, so as to achieve rich motion control function; support 32 sets of data programming at most, each of which can set pulse numbers or angle according to needs, and can set the speed , acceleration, deceleration and emergent deceleration

3、Automatically measure the mechanical properties of load inertia, configure optimal gain, reduce the commissioning time of the system

4、Make analysis of mechanical resonance frequency, configure 2 sets of notch filters, which can adjust frequency (50~ 5000Hz) and notch depth, effectively overcome low frequency resonance and vibration of mechanical end, and can set vibration frequency (1~100Hz) and vibration damping

5、The function of friction torque compensation can reduce the effect of static friction force during mechanical reversal, and improve tracking performance of instructions operating at low speed

6、Support debugging software, able to make analysis of mechanical properties, set parameters and conduct surveillance, simple and intuitive to operate.

Customized Design:

If this motor do not match with your request. Please feel free to contact with us,We can make customized shaft / winding / mounting flange / cable / connector / Encoder / Brake / Gearbox and others. We will works side-by-side with you and your team to design a motor that will fit the precise needs of your application. All Engineering and Support is done in-house.