Model: 54ZYT Series Permanent Magnet Brush DC Motor 54ZYT Series

A carbon brush, also known as a motor brush, is the small part of the motor that conducts electrical current between the stationary wires (stator) and the rotating wires (rotor) of a motor or generator. The brush is typically made up of one or more carbon blocks and can come with one or more shunts or terminals.

Brushed DC motors work by having the coil rotate inside the surrounding magnets. The rotation of the coil causes the contact between commutator and brush to alternate, therefore switching the current flow through the coil. As a result, the brushed DC motor can operate.

General Specification:

| Permanent Magnet Brush DC Motor 54ZYT Series | |||||

| Product Working: | |||||

| Ball bearing | high quality ball bearing | ||||

| magnet | hard ferrite magnet, 2 - poles | ||||

| protection | IP50 | ||||

| Insulation | -40℃~+140℃ | ||||

| Certificate | CE and ROHS | ||||

| Options: | Customized Voltage, Winding, Shaft, Mounting, and Lead Configurations, EMI/RFI Suppression Circuit, Thermal Protection, High Temperature Class H Insulation | ||||

Customized Options:

1、Customized voltage, winding, shaft, mounting, and lead configurations

2、EMI/RFI Suppression Circuit, Thermal Protection, High Temperature Class H Insulation

3、MOQ: 100Pcs

Motor Main Characteristics:

| Model | Unit | JK54ZYT-R01A | JK54ZYT-R02A | JK54ZYT-R03A | JK54ZYT-R04A |

| Rated Voltage (V) | VDC | 24v (option for 12vup to 120vdc) | |||

| Rated Speed (rpm) | Rpm | 3200 | 2580 | 2770 | 2810 |

| Rated Torque (mN.m) | N.m | 0.184 | 0.219 | 0.261 | 0.353 |

| No loadSpeed (rpm) | Rpm | 3630 | 2990 | 3150 | 3160 |

| Weight (kg) | Kg | 1 | 1.12 | 1.28 | 1.55 |

| MotorLength (mm) | Mm | 103.5 | 113 | 126 | 145 |

| Output Power (w) | W | 62 | 59 | 76 | 104 |

Note: Above only for representative products, products of special request can be made according to the customer request.

l Easy to control, a single controller can control multiple motors.

l High starting torque, and high torque at low speed

l Cheap economy

There are four types of brushed DC motors, which are suitable for different applications. You can choose according to your application.

l Permanent magnet: This type of DC motor contains a permanent magnet and has low torque. Very useful for applications that require precise control (such as robots or servo systems).

l Series connection: In this type of DC motor, the stator is connected in series with the rotor, and the speed is controlled by changing the power supply voltage. However, the speed control is quite poor: as soon as the torque increases, the speed drops. Suitable for applications that require high starting torque, such as automotive power seats or AMT.

l Parallel: In this type of DC motor, the stator and the rotor are connected in parallel, so that a higher torque can be obtained without reducing the motor current. Suitable for applications with constant speed, such as vacuum cleaners or conveyors.

l Rewinding: This type of DC motor combines the structure of a series-wound motor and a parallel-wound motor. Therefore, the starting torque is higher and the speed range is wider. Suitable for rotary machines, elevators, luggage conveyor belts, centrifugal pumps and compressors.

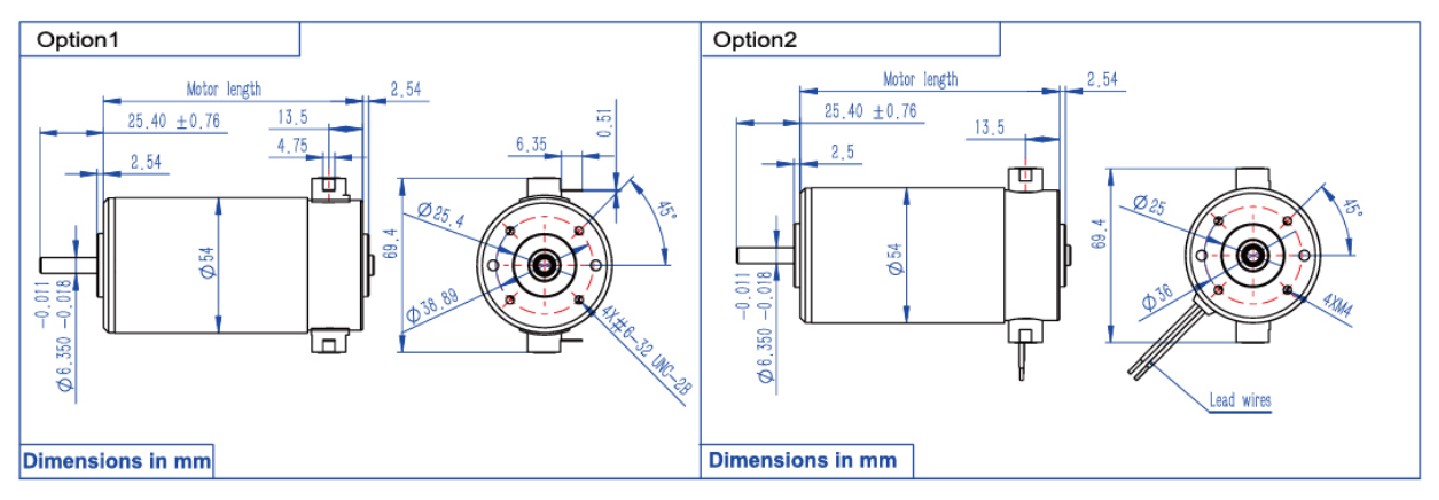

Product Dimensions: (Unit=mm)

Customized Design:

If this motor do not match with your request. Please feel free to contact with us,We can make customized shaft / winding / mounting flange / cable / connector / Encoder / Brake / Gearbox and others. We will works side-by-side with you and your team to design a motor that will fit the precise needs of your application. All Engineering and Support is done in-house.

Customized Shaft Types: