Model: Jkongmotor Pulse RS485 Canopen Integrated Stepper Linear Servo Motor with Lead Screw Hybrid Stepping Motor for 3D Printer

Integrated Step Motors fuse step motor plus drive and control components into a single device. Integrated steppers offer a space-saving design that reduces wiring and saves on cost over separate motor and drive components.

Linear Stepper Motors:These stepper motors with linear motion are open-loop systems with a base and a slider. They provide high speeds and resolutions. The sliders are also called forcers which contain a permanent magnet, teeth, and motor windings.

We are a comprehensive company which specializes in producing and researching stepper motor and motor driver, closed loop stepper motor, step servo motor, brushless dc motor, brushless dc driver, spindle motor. Our company is located in Changzhou city, Jiangsu province, China. We have an excellent group with rich experience in manufacturing and researching. We can solve the actual using problems for customers.

Our products are highly commended by customers because of its easy operation, long using life, stable performance, low failure rate and high technical content.

1. 42mm Hybrid Nema 17 Integrated Linear Stepper Servo Motor Genaral Specification:

| Name | Nema 17 Integrated Stepper Motor with Lead Screw |

| Model | Linear Stepper Motor with Integrated Driver |

| Motor Type | STM Integrated Steppers |

| Holding Torque | 0.22N.m to 0.8N.m |

| Step Angle | 1.8 degree |

| Current | 1.3A to 1.7A |

| Shaft | 5mm D-cut Shaft or round shaft |

| Support Control | Pulse / RS485 / Canopen |

| Usage | Printing, AOI, panel bonding, transfer equipment, etc. in PCB related equipment; camera related equipment such as camera and fingerprint; solid crystal machine, wire bonding machine, dispensing machine, beam splitter, and package tape machine in packaging |

2、Nema 17 Integrated Stepper Motor Details:

3,Features of integrated easy servo stepper motor with controller driver:

1、Cortex-M4 core high-performance 32-bit micro controller

2、The highest pulse response frequency can reach 200KHz

3、Built in protection function, effectively ensuring the safe use of the device

4、Intelligent current regulation to reduce vibration, noise, and heat generation

5、Adopting low internal resistance MOS, the heating is reduced by 30% compared to ordinary products

6、Voltage range: DC12V-36V

7、Integrated design with integrated drive motor, easy installation, small footprint, and simple wiring

8、Equipped with anti reverse connection function

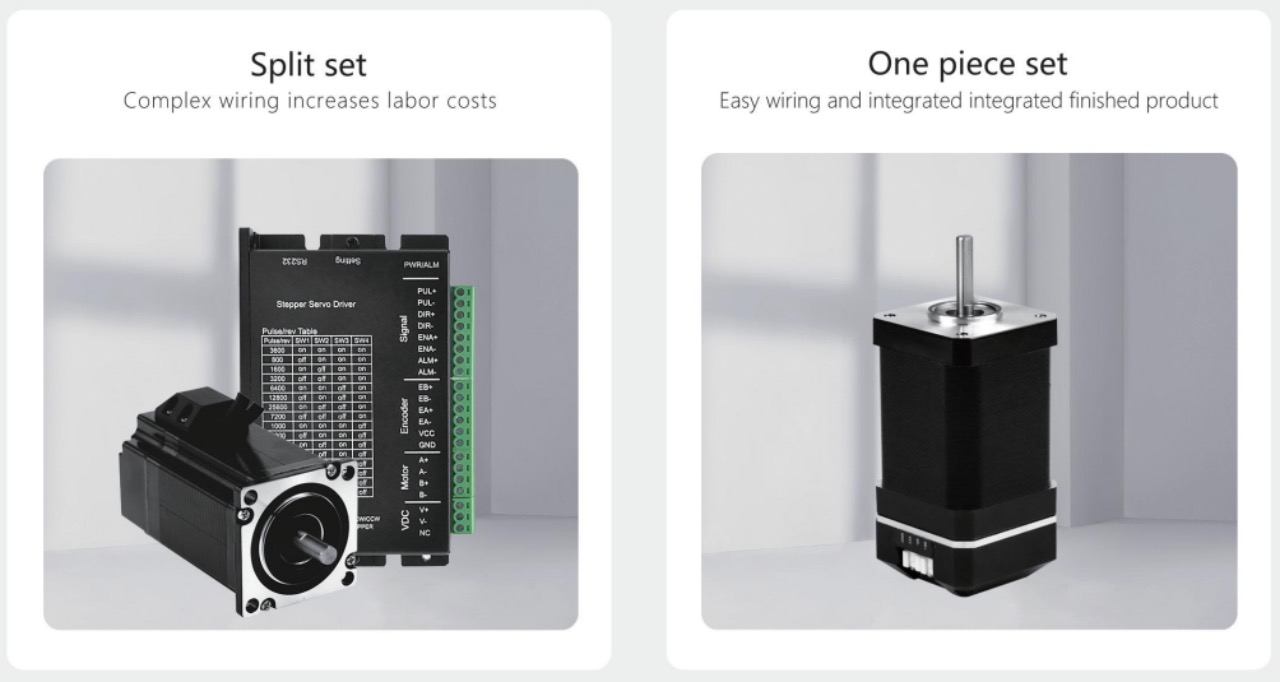

4、Traditional split solution:

5、Communication method:

1、Pulse type

2、RS485 MOdbus RTU network type

3、CANopen network type

Protection level:

Waterproof type: IP30, IP54, IP65, optional

6、Application of integrated servo stepper motor:

Medical equipment, logistics transportation, industrial automation, textile machinery, laser, drawing, traditional Chinese medicine ingredient industry, etc

7、General Specification of integrated step servo motor:

Model | Step Angle (1.8°) | phase Current (A) | Rated Resistance (0) | Rated Torque (N.m) | Total body height L (mm) | Encoder | Control method (optional) | ||

JKISS42-P01A | 1.8 | 1.3 | 2.1 | 0.22 | 54 | 1000ppr/17bit | pulse | RS485 | CANopen |

JKISS42-P02A | 1.8 | 1.68 | 1.65 | 0.42 | 60 | 1000ppr/17bit | pulse | RS485 | CANopen |

JKISS42-P03A | 1.8 | 1.68 | 1.65 | 0.55 | 68 | 1000ppr/17bit | pulse | RS485 | CANopen |

JKISS42-P04A | 1.8 | 1.7 | 3 | 0.8 | 80 | 1000ppr/17bit | pulse | RS485 | CANopen |

8、Product Dimensions: (Unit=mm)

9、Customized Design:

If this motor do not match with your request. Please feel free to contact with us,We can make customized shaft / winding / mounting flange / cable / connector / Encoder / Brake / Gearbox and others. We will works side-by-side with you and your team to design a motor that will fit the precise needs of your application. All Engineering and Support is done in-house.

10、Customized Shaft Types: