Model: NEMA17 Planetary Gearbox Stepper Motor-JK42HSP(1.8 degree)

Product Parameters:

Product Type: NEMA17 HSP Planetary Gearbox Stepper Motor

Size:42x42mm

Feature summary:Low Inertia、Low Noise、High Torque

Place of Origin:china

Minimum order quantity:10pcs

Material Science:stator, rotor, stainless steel shaft, copper wire, magnetic steel...

Applicatin Scope: 3D Printers, Monitor Equipment, Medical Machinery, Textile Machinery, Packaging Machinery, Lighting, ect.

Packing:The sample is packed in carton,the batch with plastic pallet

Delivery time:Standard product: 7-10days

Customized product: 25-30days

Transaction mode:EXW, FOB, FCA, CIF, FAS, CFR, CPT, CIP, DAF, DEQ, DDU, DDP...

Nema 17 Stepper Motor Specification:

Item | Specifications |

Step Angle | 1.8° |

Temperature Rise | 80℃max |

Ambient Temperature | -20℃~+50℃ |

Insulation Resistance | 100 MΩ Min. ,500VDC |

Dielectric Strength | 500VAC for 1minute |

Shaft Radial Play | 0.02Max. (450g-load) |

Shaft Axial Play | 0.08Max. (450g-load) |

Max. radial force | 28N (20mm from the flange) |

Max. axial force | 10N |

Electrical Specification:

Model No. | Step Angle | Motor Length | Current /Phase | Resistance /Phase | Inductance /Phase | Holding Torque | # of Leads | Detent Torque | Rotor Inertia | Mass |

( °) | (L)mm | A | Ω | mH | kg.cm | No. | g.cm | g.cm2 | Kg | |

JK42HS34-1334 | 1.8 | 34 | 1.33 | 2.1 | 2.5 | 2.2 | 4 | 120 | 34 | 0.22 |

JK42HS34-0406 | 1.8 | 34 | 0.4 | 24 | 15 | 1.6 | 6 | 120 | 34 | 0.22 |

JK42HS40-1684 | 1.8 | 40 | 1.68 | 1.65 | 3.2 | 3.6 | 4 | 150 | 54 | 0.28 |

JK42HS40-1206 | 1.8 | 40 | 1.2 | 3 | 2.7 | 2.9 | 6 | 150 | 54 | 0.28 |

JK42HS48-1684 | 1.8 | 48 | 1.68 | 1.65 | 2.8 | 4.4 | 4 | 260 | 68 | 0.35 |

JK42HS48-1206 | 1.8 | 48 | 1.2 | 3.3 | 2.8 | 3.17 | 6 | 260 | 68 | 0.35 |

JK42HS60-1704 | 1.8 | 60 | 1.7 | 3 | 6.2 | 7.3 | 4 | 280 | 102 | 0.5 |

JK42HS60-1206 | 1.8 | 60 | 1.2 | 6 | 7 | 5.6 | 6 | 280 | 102 | 0.5 |

Note: Above only for representative products, products of special request can be made according to the customer request.

Electrical Specification: PLE42-L1 Planetary Gearbox Specifications:

Electrical Specification: | |||||

Specification | PLE42-L1 | ||||

Model | PLE42-03 | PLE42-04 | PLE42-05 | PLE42-07 | PLE42-010 |

Reduction Ratio | 3:1 | 4:1 | 5:1 | 7:1 | 10:1 |

Output Torque | 8N.m | 9N.m | 9N.m | 5N.m | 5N.m |

Fail-stop Torque | 16N.m | 18N.m | 18N.m | 10N.m | 10N.m |

Suitable Motor | Φ5-10 / Φ22-2 / F31-M3 | ||||

Rated Input Speed | 3000min-1 | ||||

Max Input Speed | 6000min-1 | ||||

Average Lifespan | 20000h | ||||

Backlash | ≤15arcmin | ||||

Efficiency | 96% | ||||

Noise | ≤55dB | ||||

Work Temperature | -10°~+90° | ||||

Degree of Protection | IP54 | ||||

Weight | 0.25kg | ||||

Electrical Specification: PLE42-L2 Planetary Gearbox Specifications:

Electrical Specification: | ||||||

Specification | PLE42-L2 | |||||

Model | PLE42-012 | PLE42-015 | PLE42-016 | PLE42-020 | PLE42-025 | PLE42-028 |

Reduction Ratio | 12:1 | 15:1 | 16:1 | 20:1 | 25:1 | 28:1 |

Output Torque | 10N.m | 10N.m | 12N.m | 12N.m | 10N.m | 10N.m |

Fail-stop Torque | 20N.m | 20N.m | 24N.m | 24N.m | 20N.m | 20N.m |

Model | PLE42-035 | PLE42-040 | PLE42-050 | PLE42-070 | PLE42-100 | / |

Reduction Ratio | 35:1 | 40:1 | 50:1 | 70:1 | 100:1 | / |

Output Torque | 10N.m | 10N.m | 10N.m | 10N.m | 10N.m | / |

Fail-stop Torque | 20N.m | 20N.m | 20N.m | 20N.m | 20N.m | / |

Suitable Motor | Φ5-10 / Φ22-2 / F31-M3 | |||||

Rated Input Speed | 3000min-1 | |||||

Max Input Speed | 6000min-1 | |||||

Average Lifespan | 20000h | |||||

Backlash | ≤20arcmin | |||||

Efficiency | 94% | |||||

Noise | ≤55dB | |||||

Work Temperature | -10°~+90° | |||||

Degree of Protection | IP54 | |||||

Weight | 0.35kg | |||||

Different Gearbox Types:

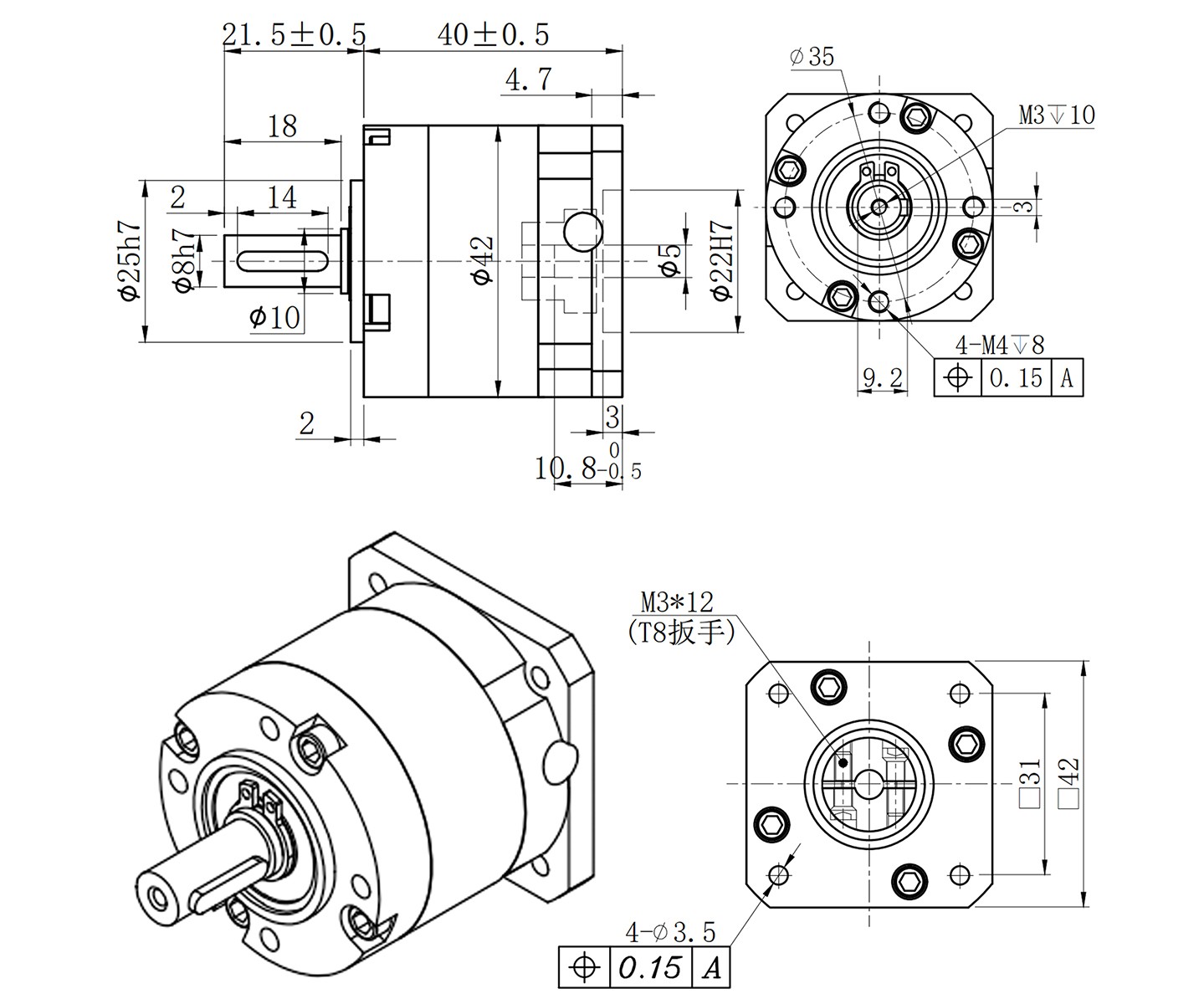

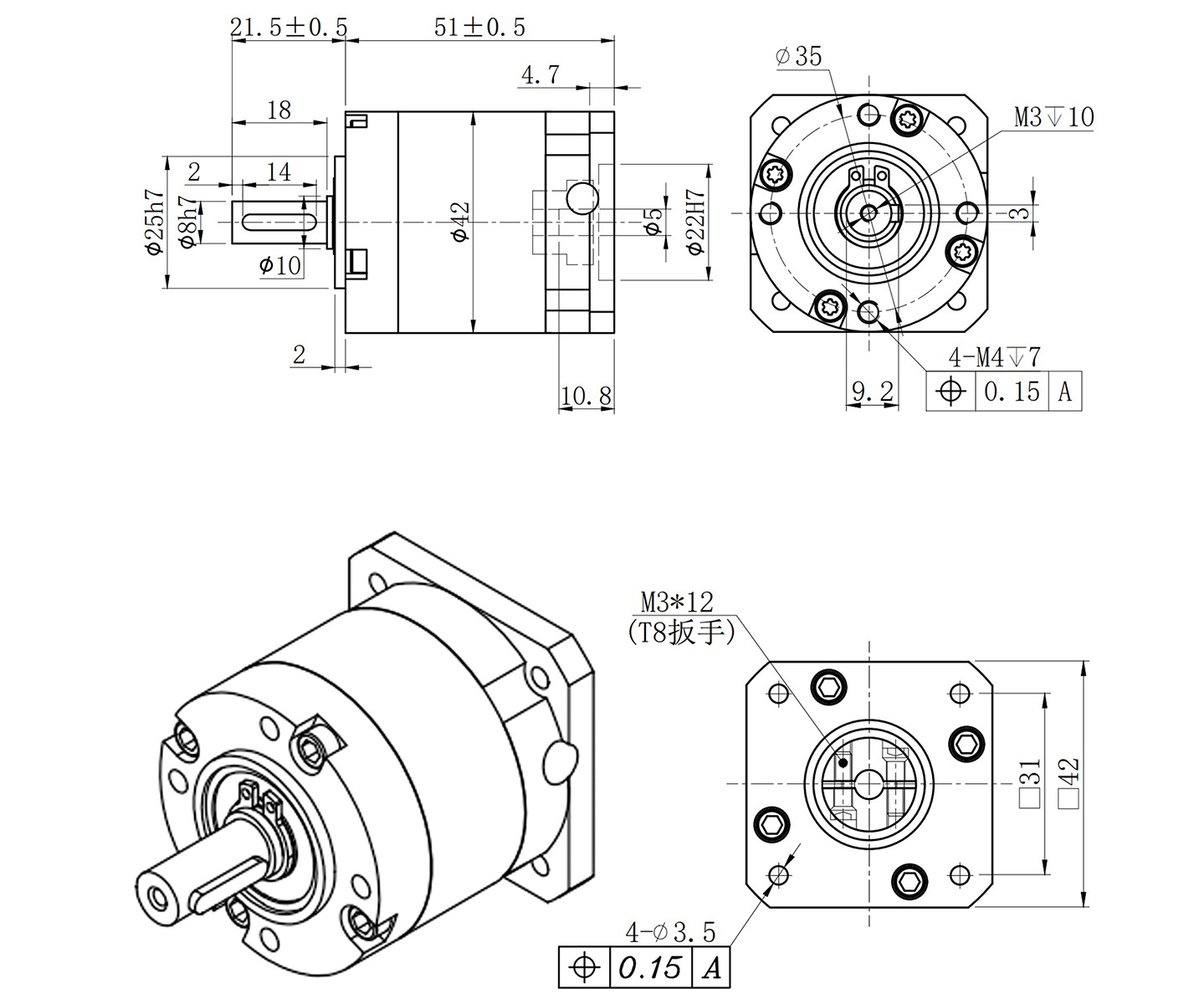

PLE42-L1 Product Dimensions: (Unit=mm)

PLE42-L1 Product Dimensions: (Unit=mm)

Customized Design:

If this motor do not match with your request. Please feel free to contact with us,We can make customized shaft / winding / mounting flange / cable / connector / Encoder / Brake / Gearbox and others. We will works side-by-side with you and your team to design a motor that will fit the precise needs of your application. All Engineering and Support is done in-house.

Customized Shaft Types: