iHSS42 / iHSS57 / iHSS86 Series Nema 17 23 24 34 Closed Loop Integrated Stepper Motor With Driver or Encoder For CNC Milling

The Integrate Stepper Servo Motor is merged the stepper servo driver and motor together. This motor system integrates the servo control technology into the digital stepper drive perfectly. And this product adopts an optical encoder with high speed position sampling feedback of 50 μ s, once the position deviation appears, it will be fixed immediately. This product is compatible the advantages of the stepper drive and the servo drive, such as lower heat, less vibration, fast acceleration, and so on.

1. 42mm Hybrid Nema 23 Integrated Stepper Motor Genaral Specification:

| Name | Nema 17 23 24 34 Integrated Servo Stepper Motor |

| Model | Closed Loop Stepper Motor with Integrated Driver |

| Motor Type | STM Integrated Steppers |

| Holding Torque | 0.48N.m to 8.5N.m |

| Current | 1.2A to 6.0A |

| Shaft | 5mm / 8mm / 14mm D-cut Shaft |

| Usage | Printing, AOI, panel bonding, transfer equipment, etc. in PCB related equipment; camera related equipment such as camera and fingerprint; solid crystal machine, wire bonding machine, dispensing machine, beam splitter, and package tape machine in packaging |

2,Features of integrated closed loop stepper motor with controller driver:

* Integrated compact size for saving mounting space

* Without losing step, High accuracy in positioning

* 100% rated output torque

* Variable current control technology, High current efficiency

* Small vibration, Smooth and reliable moving at low speed

* Accelerate and decelerate control inside, Great improvement in smoothness of starting or stopping the motor

* User-defined micro steps

* No adjustment in general applications

* Over current, over voltage and over position error protection

* Green light means running while red light means protection or off line

3,Application of integrated servo stepper motor:

Printing, AOI, panel bonding, transfer equipment, etc. in PCB related equipment; camera related equipment such as camera and fingerprint; solid crystal machine, wire bonding machine, dispensing machine, beam splitter, and package tape machine in packaging.

4,General Specification of integrated step servo motor:

| Model Name: | Holding Torque: | Voltage: | Current: | Shaft Size: | D-cut Size: | Body Length: |

| iHSS42-24-05 | 0.48N.m | 24V | 1.2A | 5*24mm | 15mm | 76mm |

| iHSS42-24-07 | 0.7N.m | 24V | 1.2A | 5*24mm | 15mm | 88mm |

| iHSS57-36-10 | 1.2N.m | 36V | 4.0A | 8*21mm | 15mm | 108mm |

| iHSS57-36-20 | 2.0N.m | 36V | 5.0A | 8*21mm | 15mm | 127mm |

| iHSS60-36-30 | 3.0N.m | 36V | 5.0A | 8*31mm | 25mm | 117mm |

| iHSS86-60-45 | 4.5N.m | 60V | 6.0A | 14*38mm | 73mm | 121mm |

| iHSS86-80-85 | 8.5N.m | 80V | 6.0A | 8*21mm | 73mm | 141mm |

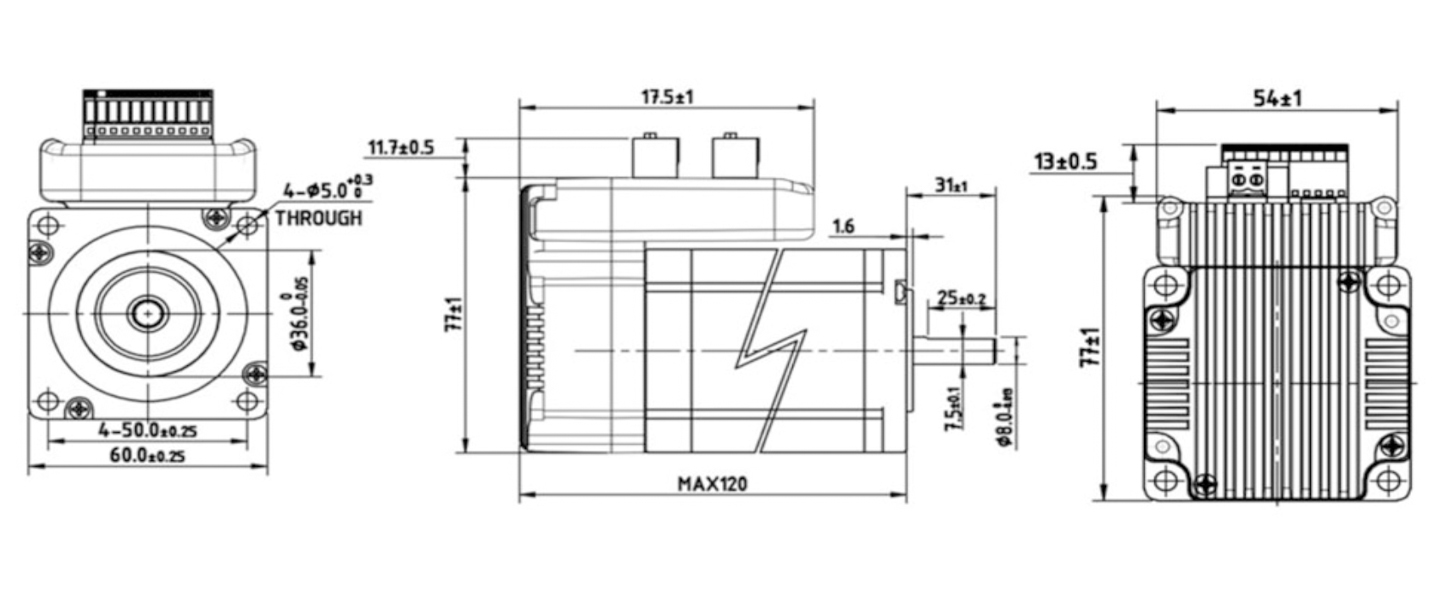

5,Product Dimensions: (Unit=mm)

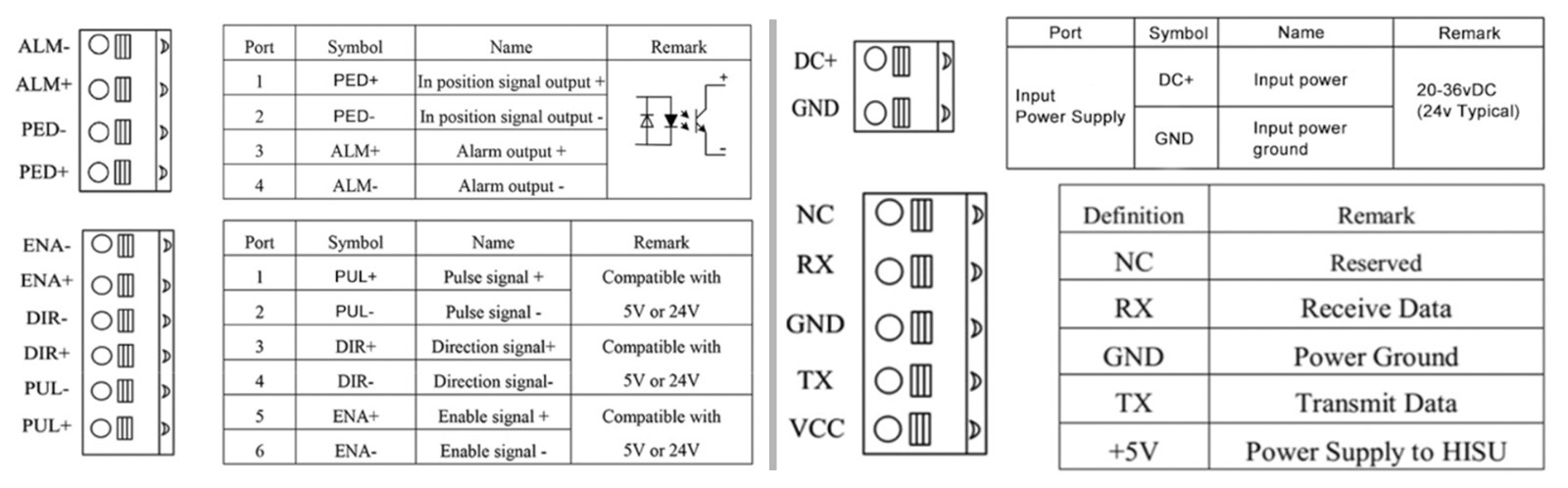

6,Terminal Description:

7,Micro Steps Settings:

| Dial switch /Micro steps | SW1 | SW2 | SW3 | SW4 |

| Default | on | on | on | on |

| 800 | off | on | on | on |

| 1600 | on | off | on | on |

| 3200 | off | off | on | on |

| 6400 | on | on | off | on |

| 12800 | off | on | off | on |

| 25600 | on | off | off | on |

| 51200 | off | off | off | on |

| 1000 | on | on | on | off |

| 2000 | off | on | on | off |

| 4000 | on | off | on | off |

| 5000 | off | off | on | off |

| 8000 | on | on | off | off |

| 10000 | off | on | off | off |

| 20000 | on | off | off | off |

| 40000 | off | off | off | off |

6,Customized Design:

If this motor do not match with your request. Please feel free to contact with us,We can make customized shaft / winding / mounting flange / cable / connector / Encoder / Brake / Gearbox and others. We will works side-by-side with you and your team to design a motor that will fit the precise needs of your application. All Engineering and Support is done in-house.

7,Customized Shaft Types: