Model: Jkongmotor 60mm Pulse / ModBus / Canopen Communication Integrated Dc Servo Motor with Worm Gearbox

Worm drives are compact gearboxes with high output torque for their size. This particular gearbox is suitable for 60x60mm or 57x57mm stepper motors or brushless dc motors and is compatible with RV30 Series 14mm output shafts. The input shaft is 9mm and you will couple to a rotating power source - typically through a jaw coupling, timing belt pulley or chain sprocket.

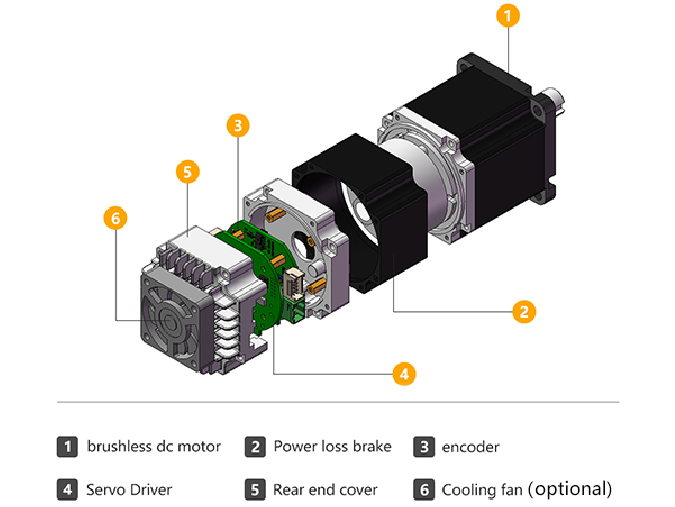

The integrated servo motor, as the name suggests, is a servo motor that integrates the motor, encoder, and driver into one. The integrated servo motor is a servo system developed based on the DC low-voltage power supply method, using permanent magnet synchronous motor and FOC drive mode. At the same time, it supports EtherCAT, CANopen, Modbus and other bus mode control, which has higher integration advantages.

Jkongmotor's integrated DC servo motors offer a perfect blend of advanced technology, customization options, and robust performance, making them an ideal choice for various industrial and commercial applications. Whether it's precision control, high-speed operation, or reliable performance in challenging environments, these motors are designed to deliver exceptional results.

The ability to customize motor parameters, control methods, and integrated designs for specific application requirements sets Jkongmotor apart in the market. This level of flexibility ensures that customers can find the perfect solution for their unique needs, whether it's in the field of medical equipment, industrial automation, or any other specialized industry.

The motors' wide range of control options, from pulse type to network-based control, provides further versatility, allowing seamless integration into diverse systems and equipment. Additionally, the robust protection features and varying protection ratings make these motors suitable for deployment in environments with different levels of exposure to dust, water, and other elements.

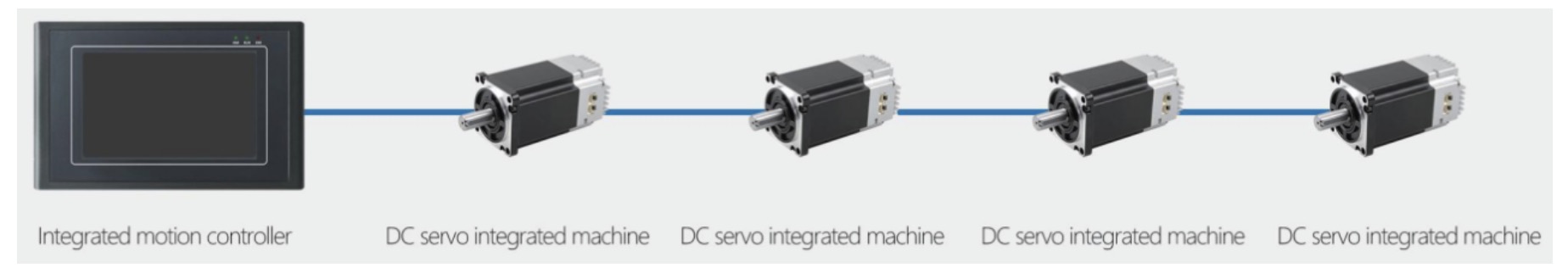

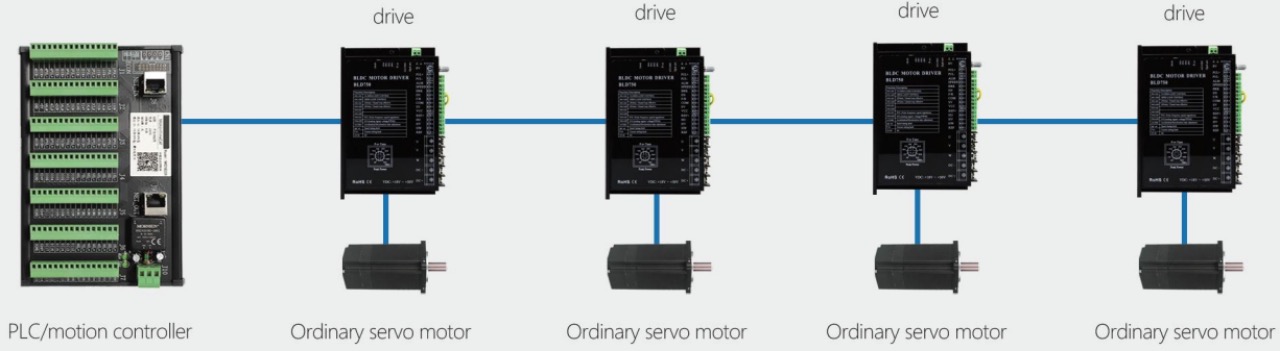

Integrated solution for precision control motors:

Traditional split solution:

3. Integrated single-turn absolute value encoder, zero point memory within limited range; integrated I / O, can be set to positive limit, negative limit, origin, multi-function digital output, pulse input detection.

The integrated servo motor adopts the integrated design of drive + coding + motor + a small number of cables, which makes the drive and motor adaptation more perfect, eliminating the matching process between the drive and the motor, and enabling rapid deployment without the bloated control cabinet design, which reduces The cost.

The integrated servo motor is a servo system developed based on the DC low-voltage power supply method, using permanent magnet synchronous motor and FOC drive mode. At the same time, it supports EtherCAT, CANopen, Modbus and other bus mode control, which has higher integration advantages.

Dc servo motors are normally used as prime movers in computers, numerically controlled machinery, or other applications where starts and stops are made quickly and accurately. Servo motors have lightweight, low-inertia armatures that respond quickly to excitation-voltage changes.

60mm 200w 400w 0.64nm 1.27nm integrated dc servo motor

Features :

1、 Adopting a new 32-bit M4+core with 120M or 240M main frequency

2、 Stable torque characteristics from low to high speeds, with high speed and precision

3、 Equipped with brake resistor interface to prevent damage to the electromechanical braking system

4、Wide speed range, low temperature rise, and high efficiency

5、 Integrated motor and drive, compact size, simple wiring, and drive Good compatibility with the motor

6、 Equipped with overcurrent, overvoltage, over temperature, and over differential protection functions

7、 Configure a 17 bit single turn absolute encoder

Communication method:

1、Pulse type

2、RS485 Modbus RTU network type

3、CANopen network type

Protection level:

Waterproof type: IP30, IP54, IP65, optional

Integrated Dc Servo Motor Product Parameters:

Product Type: JK60IDS Brushless DC Motor with integrated driver / Integrated Servo Motor

Size:60x60mm integrated servo motor

Place of Origin:china

Minimum order quantity:10pcs

Material Science:stator, rotor, stainless steel shaft, copper wire, magnetic steel...

Feature summary: Low Inertia,Quick Feedback; High Torque,High Efficiency; Small Vibration,Low Noise

Packing:The sample is packed in carton,the batch with plastic pallet

Delivery time:Standard product: 7-10days

Customized product: 25-30days

Transaction mode:EXW, FOB, FCA, CIF, FAS, CFR, CPT, CIP, DAF, DEQ, DDU, DDP...

APPLICATION:Medical equipment, logistics transportation, industrial automation, textile machinery, laser, drawing, traditional Chinese medicine ingredient industry, etc

Electrical Specification:

Model | Power (W) | Rated Voltage (VDC) | Rated Current (A) | Rated Speed (rpm) | Rated Torque (N.m) | Total height L (mm) | Encoder | Control method (optional) | ||

JKIDS60-P01A | 200 | 24 | 12 | 3000 | 0.64 | 94 | 17bit | pulse | RS485 | CANopen |

JKIDS60-P02A | 400 | 48 | 11 | 3000 | 1.27 | 112 | 17bit | pulse | RS485 | CANopen |

Note: Above only for representative products (bldc motor integrated controller), products of special request can be made according to the customer request.

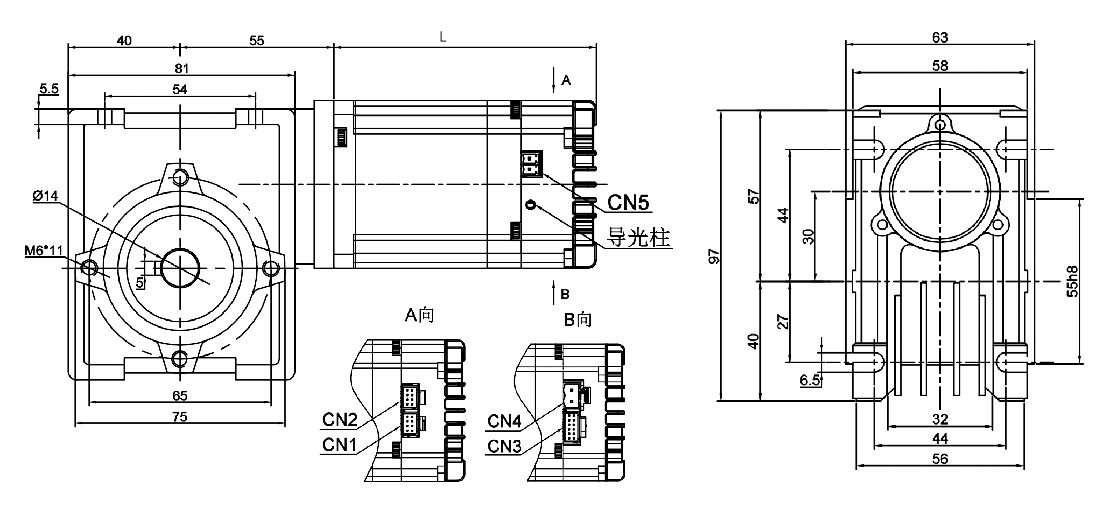

Worm Gearbox Specification:

| Model | RV30 | RV40 | RV50 | |||

| Gear Ratio | 5 / 7.5 / 10 / 15 / 20 / 25 / 30 / 40 / 50 / 60 / 80 | 5 / 7.5 / 10 / 15 / 20 / 25 / 30 / 40 / 50 / 60 / 80 | 5 / 7.5 / 10 / 15 / 20 / 25 / 30 / 40 / 50 / 60 / 80 | |||

| Output Hole Diameter/mm | 14 | 28 | 25 | |||

| Length/mm | 81 | 101 | 121 | |||

| Height/mm | 97 | 121 | 144 | |||

| Widths/mm | 58 | 73 | 87 | |||

| Input Hole Diameter/mm | 9 | 14 | 14 | |||

| Suitable Motor | 57x57mm /60x60mm | 86x86mm | 86x86mm | |||

Features of Worm Gearbox:

High quality aluminum alloy enclosure

Good heat dissipation performance

Large carrying capacity

Smooth transmission

Low noise

Worm gear reducer is widely used in many industries, its gearbox center distance is 30mm from the worm shaft to the worm wheel.The main material of the worm gear reducer is aluminum alloy. It can bear large load with small power. It is also used for middle-duty working conditions. With the advancement of technology, the price is decreasing day by day, and it is widely used. The worm gear reducer is mainly used in many industries such as the automotive industry, printing industry, medical equipment, construction machinery, machinery equipment, paper making, power industry, etc. It can change the rotation of the output shaft to make the rotation speed lower and faster. As for the ratio, it can be changed according to the application.

24v / 48v Integrated Servo Motor Product Dimensions: (Unit=mm)

JK60IDS 24v / 48v Integrated Servo Motor Details :

Customized Design:

If this motor do not match with your request. Please feel free to contact with us,We can make customized shaft / winding / mounting flange / cable / connector / Encoder / Brake / Gearbox and others. We will works side-by-side with you and your team to design a motor that will fit the precise needs of your application. All Engineering and Support is done in-house.

Customized Shaft Types: