Linear stepper motors offer significant cost savings and space efficiency. They eliminate the need for coupling, additional bearing support, and complex assembly, leading to lower expenses and a reduced risk of failure due to fewer components and simpler designs. In applications with lighter loads, a linear guide is often unnecessary. Moreover, the unique design and materials used in the nut ensure long-lasting operation.

In the case of linear actuators with linear guide (captive), the plastic threaded nut is injection-molded into the hollow shaft rotor of the stepper motor and positively connected to it. If the motor is energized, the connection of lead screw and threaded nut transforms the rotary motion of the rotor into the linear motion of the lead screw. For this purpose, a linear guide is attached to the front of the lead screw and prevents the lead screw from rotating.

The best-selling designs provide exceptional performance, creating new opportunities for equipment designers who previously opted for products with lower performance and durability.

This series comes in a broad range of resolutions, ranging from 0.00006 inches (0.001524 mm) per step to 0.00192 inches (0.048768 mm) per step. It offers thrust capabilities of up to 50 lbs (222 N) and can achieve speeds greater than 3 inches (7.62 cm) per second.

1. It has a threaded drive screwheld mostly inside the motor body which connected to a spline.

2. It has a built in anti-rotation though the use of a spline shaft that allows it to extend and retact as a unit with no requirements for additional anti-rotation.

3. The captive actuator is designed for shorter strokes up to about three inches, the basic design is least tolerant of system misalignment and is the most protective actuator style, beacuse it is self contained. The captive has the longest basic body style.

Compact linear guide

Two motor lengths per NEMA size

Various windings

Different stroke lengths and lead screw versions

Can optionally be configured with encoder

Integrated connector

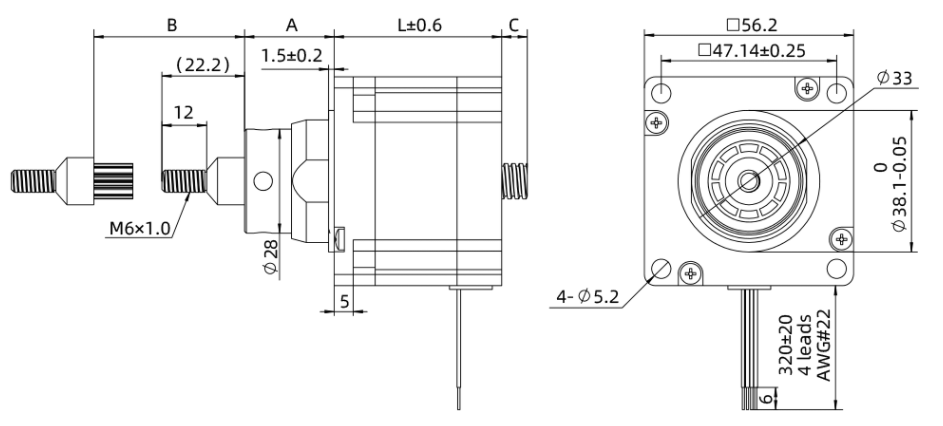

Product Type: Nema 23 Hybrid Stepper Motor Linear Actuators

Place of Origin:china

Minimum order quantity:5pcs

Material Science:stator, rotor, stainless steel shaft, copper wire, magnetic steel...

Feature summary: Low Inertia,Quick Feedback; High Torque,High Efficiency; Small Vibration,Low Noise

Packing:The sample is packed in carton,the batch with plastic pallet

Delivery time:Standard product: 7-10days

Customized product: 25-30days

Transaction mode:EXW, FOB, FCA, CIF, FAS, CFR, CPT, CIP, DAF, DEQ, DDU, DDP...

APPLICATION:JKONGMOTOR linear stepping motor is a motor that converts electrical pulse signals into corresponding angular displacements or linear displacements. This small linear actuator stepper motor can be widely used in various fields, such as a 3D printer, stage lighting, laser engraving, textile machinery, medical equipment, automation equipment, etc.

| Model No. | Step Angle | Motor Length | Current | Resistance | Inductance | Holding Torque | # of Leads | Rotor Interia | Mass |

| ( °) | (L)mm | A | Ω | mH | N.m | No. | g.cm2 | kg | |

| JK57HSK41-2804 | 1.8 | 41 | 2.8 | 0.7 | 1.4 | 0.55 | 4 | 150 | 0.47 |

| JK57HSK51-2804 | 1.8 | 51 | 2.8 | 0.83 | 2.2 | 1 | 4 | 230 | 0.59 |

| JK57HSK56-2804 | 1.8 | 56 | 2.8 | 0.9 | 3 | 1.2 | 4 | 280 | 0.68 |

| JK57HSK76-2804 | 1.8 | 76 | 2.8 | 1.1 | 3.6 | 1.89 | 4 | 440 | 1.1 |

| JK57HSK82-3004 | 1.8 | 82 | 3 | 1.2 | 4 | 2.1 | 4 | 600 | 1.1 |

| JK57HSK100-3004 | 1.8 | 100 | 3 | 0.75 | 3 | 2.8 | 4 | 700 | 1.3 |

| JK57HSK112-3004 | 1.8 | 112 | 3 | 1.6 | 7.5 | 3 | 4 | 800 | 1.4 |

Note: Above only for representative products, products of special request can be made according to the customer request.

If this motor do not match with your request. Please feel free to contact with us,We can make customized shaft / winding / mounting flange / cable / connector / Encoder / Brake / Gearbox and others. We will works side-by-side with you and your team to design a motor that will fit the precise needs of your application. All Engineering and Support is done in-house.