Model: NEMA23 2Phase Hybrid Bipolar Spur Gearbox Stepper Motor-JK57HSP(1.8 degree)

Jkongmotor proudly presents its range of Nema23 geared stepper motors, designed to meet the diverse needs of automation and precision control applications. With a robust construction and advanced gearing system, these motors provide reliable performance and high torque, making them ideal for both industrial and commercial use. The range features gear ratios that vary from 3:1 to an impressive 150:1, allowing users to optimize the motor's performance for various tasks, whether it be in robotics, CNC machinery, or other precision engineering solutions.

Our Spur Geared Stepper Motors, part of the Jkongmotor portfolio, offer exceptional efficiency and accuracy, tailored to provide smooth motion control across a broad spectrum of applications. The innovative spur gear design enhances the power output while maintaining a compact form factor, allowing for easy integration into existing systems. With gear ratios spanning from 3:1 to 150:1, these stepper motors equip engineers and designers with the versatility they require to tackle complex projects with confidence and ease.

Gearbox is a mechanical unit or component consisting of a series of integrated gears within a housing. In the most basic sense, a gearbox functions like any system of gears, it alters torque and speed between a driving device like a motor and a load. Spur gearboxes, smooth and quiet operation, wide range of gear ratios, long life, and maximum efficiency.

In summary, Jkongmotor's Nema23 geared and spur geared stepper motors are engineered to deliver high-performance solutions for your mechanical needs. The ability to select from a wide range of gear ratios enables customization for specific applications, ensuring optimal productivity and efficiency. Investing in Jkongmotor means equipping your projects with reliable and technologically advanced motor solutions that uphold the highest standards of engineering excellence.

The role of spur gearbox

Stepper motors are known for their accurate positioning capabilities and high torque delivery at low speeds, but they require careful sizing to ensure the motor matches the load and application parameters, to minimize the possibility of lost steps or motor stalling. Adding a gearbox to a stepper motor system can improve the motor’s performance by decreasing the load-to-motor inertia ratio, increasing torque to the load, and reducing motor oscillations.

Spur Gearboxes Features:

● High torque and low noise.

● Low-temperature rise and stable operation.

● Economical.

● Low speed with low vibration

● Self-detection, over-current, over-voltage, under-voltage protection

● Customization is available

General Specification:

Housing Material | Metal |

Bearing at Output | Ball Bearings |

Max.Radial Load(12mm from flange) | ≤20N |

Max.Shaft Axial Load | ≤15N |

Radial Play of Shaft (near to Flange) | ≤0.06mm |

Axial Play of Shaft | ≤0.3mm |

Backlash at No-load | 1.5° |

Product Parameters:

Product Type: NEMA23 Spur Eccentric Gearbox Stepper Motor

Size:57x57mm

Feature summary:Low Inertia、Low Noise、High Torque

Place of Origin:china

Minimum order quantity:10pcs

Material Science:stator, rotor, stainless steel shaft, copper wire, magnetic steel...

Applicatin Scope: 3D Printers, Monitor Equipment, Medical Machinery, Textile Machinery, Packaging Machinery, Lighting, ect.

Packing:The sample is packed in carton,the batch with plastic pallet

Delivery time:Standard product: 7-10days

Customized product: 25-30days

Transaction mode:EXW, FOB, FCA, CIF, FAS, CFR, CPT, CIP, DAF, DEQ, DDU, DDP...

Nema 23 Bipolar Steper Motors Electrical Specification:

Model No. | Step Angle | Motor Length | Current /Phase | Resistance /Phase | Inductance /Phase | Holding Torque | # of Leads | Detent Torque | Rotor Inertia | Mass |

( °) | (L1)mm | A | Ω | mH | N.m | No. | g.cm | g.cm2 | Kg | |

JK57HS41-2804 | 1.8 | 41 | 2.8 | 0.7 | 1.4 | 0.55 | 4 | 250 | 150 | 0.47 |

JK57HS51-2804 | 1.8 | 51 | 2.8 | 0.83 | 2.2 | 1.01 | 4 | 300 | 230 | 0.59 |

JK57HS56-2804 | 1.8 | 56 | 2.8 | 0.9 | 2.5 | 1.2 | 4 | 350 | 280 | 0.68 |

JK57HS64-2804 | 1.8 | 64 | 2.8 | 0.8 | 2.3 | 1 | 4 | 400 | 300 | 0.75 |

JK57HS76-2804 | 1.8 | 76 | 2.8 | 1.1 | 3.6 | 1.89 | 4 | 600 | 440 | 1.1 |

JK57HS82-3004 | 1.8 | 82 | 3 | 1.2 | 4 | 2.1 | 4 | 1000 | 600 | 1.2 |

JK57HS100-4204 | 1.8 | 100 | 4.2 | 0.75 | 3 | 3 | 4 | 1100 | 700 | 1.3 |

JK57HS112-4204 | 1.8 | 112 | 4.2 | 0.9 | 3.8 | 3.1 | 4 | 1200 | 800 | 1.4 |

Note: Above only for representative products, products of special request can be made according to the customer request.

Electrical Specification: 57HS Spur Eccentric Gearbox Specifications

Reduction ratio | 3 | 7.5 | 12.5 | 15 | 25 | 30 | 50 | 75 | 90 | 100 | 120 | 150 |

Number of gear trains | 2 | 3 | 4 | 5 | ||||||||

(L2)Length: (mm) | 32&42 | 42 | ||||||||||

Peak torque: (kg.cm) | 50 | |||||||||||

Backlash at Noload: (°) | 4 deg | 3.5deg | 3deg | 2.5deg | ||||||||

Different Gearbox Types:

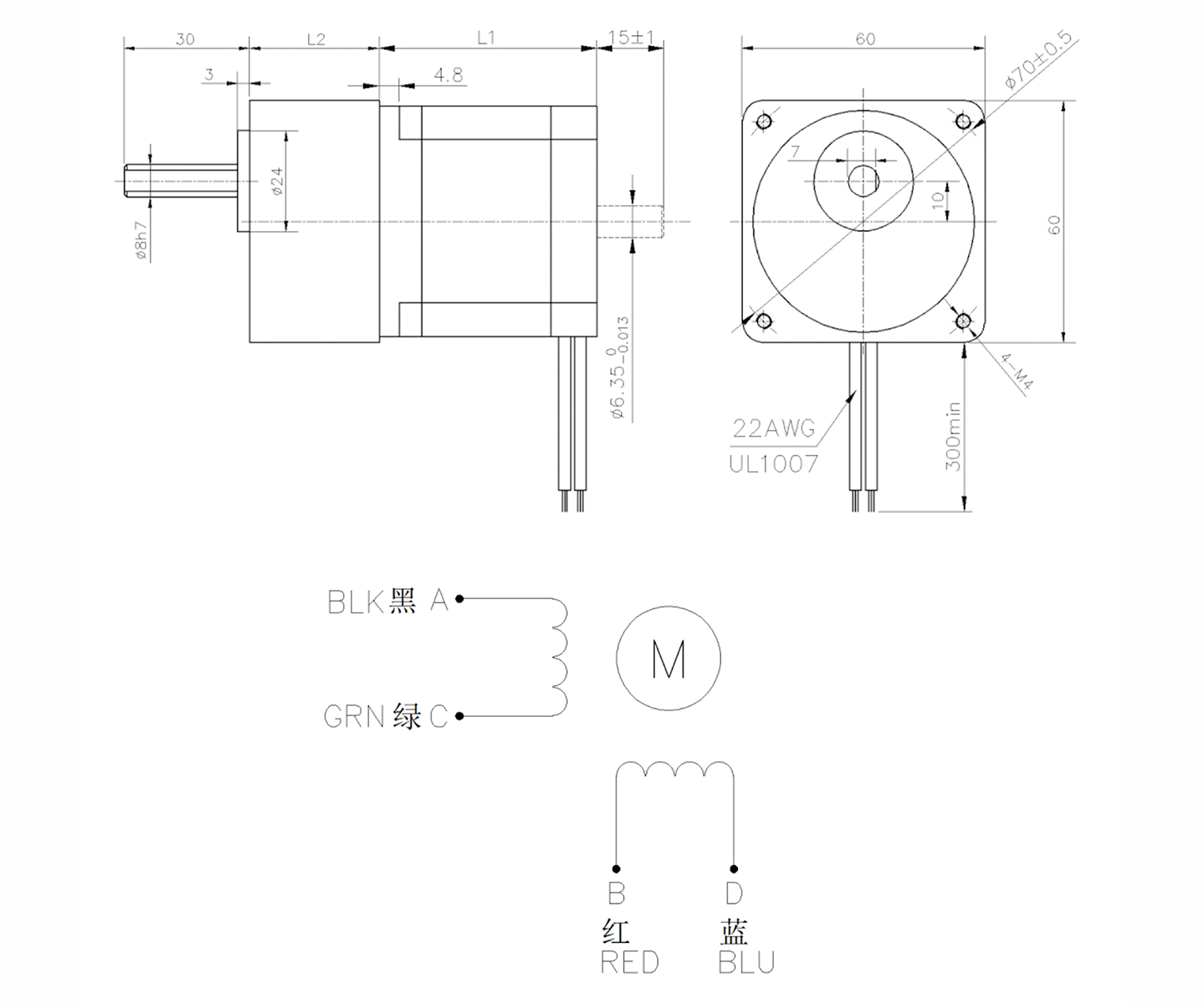

Product Dimensions: (Unit=mm)

Customized Design:

If this motor do not match with your request. Please feel free to contact with us,We can make customized shaft / winding / mounting flange / cable / connector / Encoder / Brake / Gearbox and others. We will works side-by-side with you and your team to design a motor that will fit the precise needs of your application. All Engineering and Support is done in-house.

Customized Shaft Types: