Model: Jkongmotor PLF60 60mm Square Head High Precision Planetary Gearbox Reducer for 57mm 60mm Brushless dc Motor

In the planetary gear system, the axes of the gears are usually parallel to each other and are concentric. Disadvantages include high bearing load, inaccessibility, and design complexity. However, the advantages of planetary gears over parallel axis gears are compact size, higher efficiency, and low noise level.

Units with standard planetary gearheads with 1 or 2 stages are generally considered back-drivable. It is just possible that the mechanical misalignment between motor and 1-stage gearheads might lead to a notchy behavior in forward direction and reduced back-drivability in backward direction.

One potential disadvantage of planetary gear sets is power losses due to multiple planet branches, resulting from an increased number of gear meshes and bearings. The power losses of a planetary gear set can be grouped in two categories based on their dependence on load.

The 60mm BLDC motor has a 24V DC input and is compatible with the planetary gearboxes. It has a rated speed of 4000 rpm, a maximum speed of 8000 rpm, and a maximum output torque of 15-80 Nm depending on the gear ratio. It also has a low noise level of ≤58 dB and a high efficiency of up to 96%. Its rotation direction is input/output syntropy, and its protection class is IP65. The motor can be mounted in any position.

General Specification of PLF60 High Precision Planetary Gearbox:

| PLF60 | ||||||

| Stage | Ⅰ Stage | Ⅱ Stage | Ⅲ Stage | |||

| Ratio | 3、4、5、7、10 | 12、15、16、20、25、28、35、40、50、70、100 | 64、80、100、120、125、140、175、200、250、280、350、400、500、700、1000 | |||

| A | B | A | B | A | B | |

| Length (mm) | 42 | 110 | 59 | 127 | 76 | 144 |

| Rated Speed (rpm) | 4000 | 4000 | 4000 | |||

| Max Speed (rpm) | 8000 | 8000 | 8000 | |||

| Max. radial force (N) | 320 | 320 | 320 | |||

| Max. axial force (N) | 280 | 280 | 280 | |||

| No-load Torque (N.m) | 0.6 | 0.3 | 0.3 | |||

| Efficiency (%) | 96 | 94 | 90 | |||

| Backlash (arcmin) | ≤10 | ≤15 | ≤18 | |||

| Noise (dB) | ≤58 | ≤58 | ≤58 | |||

| Weight (kg) | 1.1 | 1.3 | 1.5 | |||

| Working Lifetime (h) | >20000 (Continuous operating life halved) | |||||

| Torsional rigidity (Nm/arcmin) | 2.3 | |||||

| Lubrication Method | Long-term | |||||

| Rotation Direction | Input/Output Syntropy | |||||

| Protection Class | IP65 | |||||

| Mounting Position | Arbitrarily | |||||

60mm BLDC Motor Planetary Gearboxes Electrical Specification:

| 减速比 Ratio(i) | Ⅰ Stage | Ⅱ Stage | ||||||||||||||

| 3 | 4 | 5 | 7 | 10 | 12 | 15 | 16 | 20 | 25 | 28 | 35 | 40 | 50 | 70 | 100 | |

| 额定输出扭矩 (Nm) | 15 | 30 | 27 | 20 | 9 | 15 | 15 | 35 | 35 | 30 | 35 | 30 | 35 | 30 | 22 | 10 |

| 最大输出扭矩 (Nm) | 30 | 60 | 54 | 40 | 18 | 30 | 30 | 70 | 70 | 60 | 70 | 60 | 70 | 60 | 44 | 20 |

| 转动惯量(kgcm² ) | 0.135 | 0.093 | 0.078 | 0.072 | 0.064 | 0.135 | 0.135 | 0.088 | 0.075 | 0.075 | 0.070 | 0.064 | 0.076 | 0.064 | 0.075 | 0.076 |

| Ⅲ Stage | ||||||||||||||||

| 减速比 Ratio(i) | 64 | 80 | 100 | 120 | 125 | 140 | 175 | 200 | 250 | 280 | 350 | 400 | 500 | 700 | 1000 / | |

| 额定输出扭矩 (Nm) | 40 | 40 | 40 | 40 | 35 | 40 | 35 | 40 | 35 | 40 | 35 | 40 | 35 | 25 | 12 | |

| 最大输出扭矩 (Nm) | 80 | 80 | 80 | 80 | 70 | 80 | 70 | 80 | 70 | 80 | 70 | 80 | 70 | 50 | 24 | |

| 转动惯量(kgcm² ) | 0.076 | 0.064 | 0.075 | 0.064 | 0.064 | 0.064 | 0.064 | 0.064 | 0.064 | 0.064 | 0.064 | 0.064 | 0.064 | 0.064 | 0.064 | |

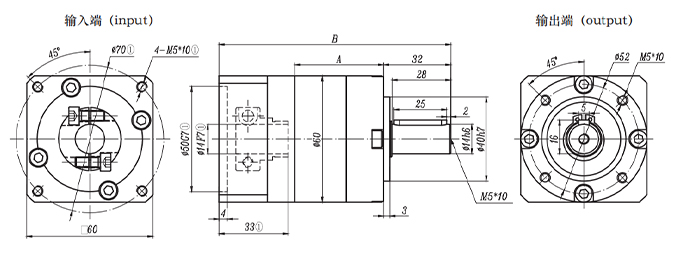

Planetary Gearbox Drawing:

Product Parameters:

Product Type: JKPLF60 Round Planetary Gearbox Reducer for Geared BLDC Motor

Place of Origin:china

Minimum order quantity:10pcs

Material Science:stator, rotor, stainless steel shaft, copper wire, magnetic steel...

Feature summary: Low Inertia,Quick Feedback; High Torque,High Efficiency; Small Vibration,Low Noise

Packing:The sample is packed in carton,the batch with plastic pallet

Delivery time:Standard product: 7-10days

Customized product: 25-30days

Transaction mode:EXW, FOB, FCA, CIF, FAS, CFR, CPT, CIP, DAF, DEQ, DDU, DDP...

APPLICATION:Medical equipment: medical pumps, stirring instruments, peristaltic pumps, biopharmaceutical equipment. Industrial equipment: winding machines, printing machines, robots, grinding, cutting, drilling, automatic conveying systems, automatic positioning systems, level control systems, electric actuators, electric valves, vending machines.

Customized Gearbox Design:

Customized Design:

If this motor do not match with your request. Please feel free to contact with us,We can make customized shaft / winding / mounting flange / cable / connector / Encoder / Brake / Gearbox and others. We will works side-by-side with you and your team to design a motor that will fit the precise needs of your application. All Engineering and Support is done in-house.

Customized Shaft Types:

Matched Brushless Motors:

Brushless DC Motor Model: 57mm BLDC Motor / 60mm Brushless DC Motor